Tilting platforms serve to unload all products with different types of vehicles. The tilting platform is operated manually on site. Cleaning systems after intake are used to clean the bulk material of dirt such as stones or other debris.

Grain dryers are used to dry products such as grain, corn or rice. Our dryers are characterized by a long life and a consistent drying process.

Transportation equipment such as trough chain conveyors or bucket elevators are used for the horizontal or vertical transport of bulk goods between storage or production.

Horizontal mixer are used to mix different components as grain, oil and vitamins. Even with high mixing quantities a very accurate mixing accuracy (1: 100,000) is given. Hammer mills are provided for the milling of grain, fiber, granules or similar products in the feed production.

Premix plants are used to dose microcomponents into the feed. A weighing scale below the feeders gives very high accuracy.

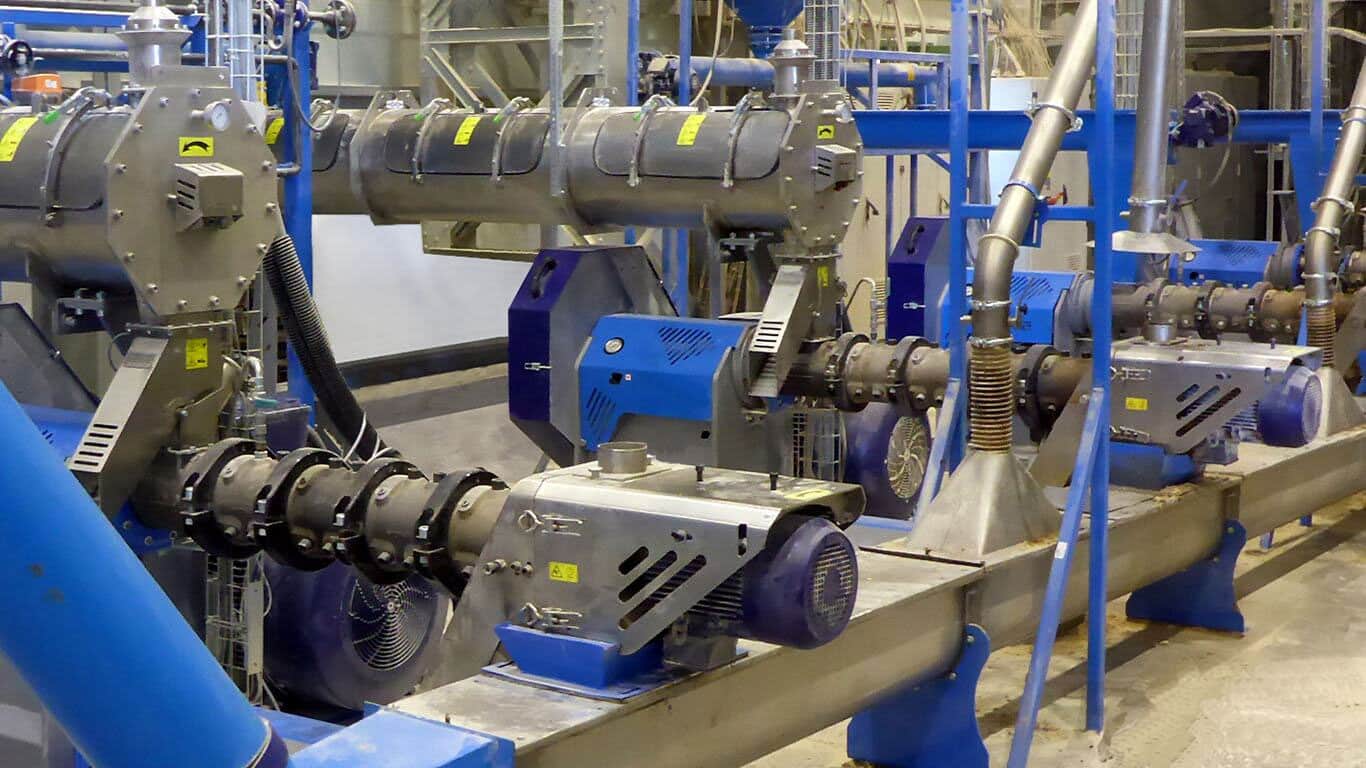

The pellet press is a machine that is used for the production of pellets from flour mixtures or other byproducts such as biogas. The feed is transported by a feeding screw into the mixer. From the mixer, the products falls into the press where the mixure is forced through the die by to rollers, thereby forming the pellets. The pellet press is available with a capacity of 200 kg/h to ≥ 45 t/h.

The extruder is used to convert grain feed into a more usable and healthier form of pet food and fish food. The extruder is designed for heat treatment of loose products such as loose compound feed, crushed soybeans, oil cake and other products, pre-saturated with steam and liquids.

An automatic control system provides full automation and monitoring of all grain warehouse and factory processes. Continuous product capture and traceability of raw and finished products is possible with the help of the controller. Over the Internet, errors can be fixed remotely. There is a hedge of production through a second server.

Mobile milling and mixing plants offer the possibility to mill and mix the goods directly in the warehouse. For this purpose, the system is connected to a tractor and driven to the warehouse and operated there by the tractor. The required power of the tractor depends on the mobile grinding and mixing system.

Silos are used in feed plants to store various products before they are handled.

Bagging systems are used to fill the manufactured product in bags and seal them. The bags are available from 1 kg to 50 kg. It can be filled and sealed up to 1.200 bags per hour.